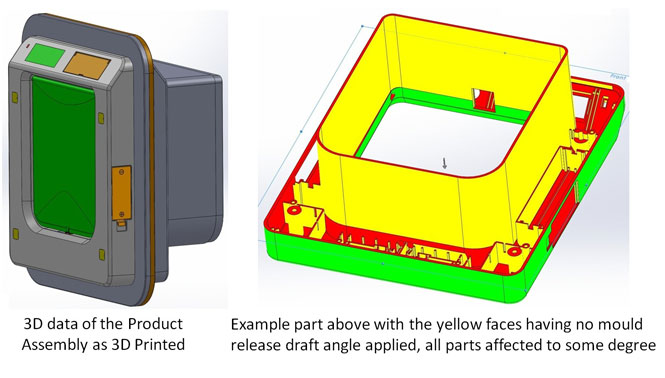

Pet Corp came to Design Smart recently with what they had believed to be a completed 3D SolidWorks product design for an electronic cat door. They had two completed functional prototype assemblies made up of 3D printed plastic parts and electronic components. However, upon sending the 3D CAD data to China for plastic injection mould tooling of the plastic parts, the immediate message returned was “cannot tool / mould these parts”. On inspection by Design Smart of the 3D models it became immediately apparent that whoever had done the mechanical CAD design work was an inexperienced designer with very little or no manufacturing experience. The parts and product assembly may have looked O.K. and fitted together quite well but there was either very little or no mould draft applied to the part models. Also the 3D modelling techniques used were very ad hoc, meaning that there were lots of independent features in the 3D part data with no clear top down assembly / part modelling strategy having being employed. This would have made rectification of the data suitable for production very difficult (which is what Pet Corp wanted us to do). To fix the lack of mould draft on the parts and also the other impractical moulding geometry that had been designed, it would have needed to have been a complete assembly and parts rebuild in SolidWorks. This complete SolidWorks remodel would have been needed to resolve all the issues with the design in the most expedient fashion. The cost and time involved to produce this full re-model was prohibitive, as there were other issues such as the mechanical locking system they had in the design which would have needed significant attention.

The owner of the business was very frustrated as he had asked around as to whom to get to do the mechanical design work. His mistake was to use someone with little or no manufacturing experience, but this is where the Industrial Design School(s) he had asked had sent him.

The worst thing being that, not only had they spent their development money of approx. $200,000 but they also had consumed the best part of 2 years in the process. By this time a competitor had well and truly beaten them to the market place, hence opportunity lost, given first to market is critical.

In summary it is very easy for the uninitiated to be fooled by working prototypes that have been 3D printed, as you can basically print any shape with no regard to the final production processes required. At Design Smart we always model with production intent from the beginning, unless it is specifically asked for otherwise, for example if it will only ever be a 3D printed product. It doesn’t take that much extra time (if at all) to do this from the beginning, while also incorporating a top down design approach for ease of future design modification. In essence as illustrated in this story there is little point in modelling a plastic injection moulded product any way other than suitable for final production moulding. This method also highlights any potential problems as early as possible in the development cycle, given that the further down the development cycle you get, the greater become the costs of any rectification. This strategy is simply a no brainer, at least to the initiated.